Discover the Durability and Quality of litho printing

Wiki Article

A Comprehensive Guide to Comprehending Litho Printing Strategies

The world of litho printing, a technique originating from the late 18th century, is a fascinating blend of history, advancement, art and scientific research. Remain with us as we journey into the fascinating realm of litho printing.The Historical Advancement of Litho Printing

The historical trajectory of litho printing, an essential innovation in the world of communication, is a captivating story of human ingenuity. The process advanced with the development of the rotary press, which substantially enhanced productivity. Each stage of litho printing's evolution showcases mankind's unrelenting quest of efficiency and top quality in visual communication.Translating the Science Behind Litho Printing Inks

Relocating forward in the expedition of litho printing methods, the emphasis currently changes to the scientific research behind litho printing inks. The composition of these inks, their drying process, and shade mixing strategies form the foundation of this complicated art type. Understanding these aspects is essential to understanding the craft and achieving the desired print results.Composition of Litho Inks

In lithographic printing, the basic role of litho inks can not be overstated. Pigments, the color-providing aspects, are finely ground particles suspended in the vehicle, a fluid that brings the pigment onto the printing surface. Each element plays a vital component in the final print's top quality, making the accurate solution of litho inks an intricate scientific research.Ink Drying Refine

From the make-up of litho inks, attention transforms to the remarkable procedure of ink drying. The drying out procedure is important, as it impacts the final print's high quality and longevity. 2 main methods are made use of in litho printing: oxidative drying out and absorption. Oxidative drying includes the ink reacting with oxygen airborne to form a tough, completely dry film. This method provides a durable surface, yet can be slower contrasted to absorption. Absorption, on the various other hand, includes the ink permeating right into the paper fibers, which is a much faster process however can bring about less lively colors. The option between these approaches depends on factors such as print speed demands, the paper kind utilized, and the desired coating.Shade Combining Techniques

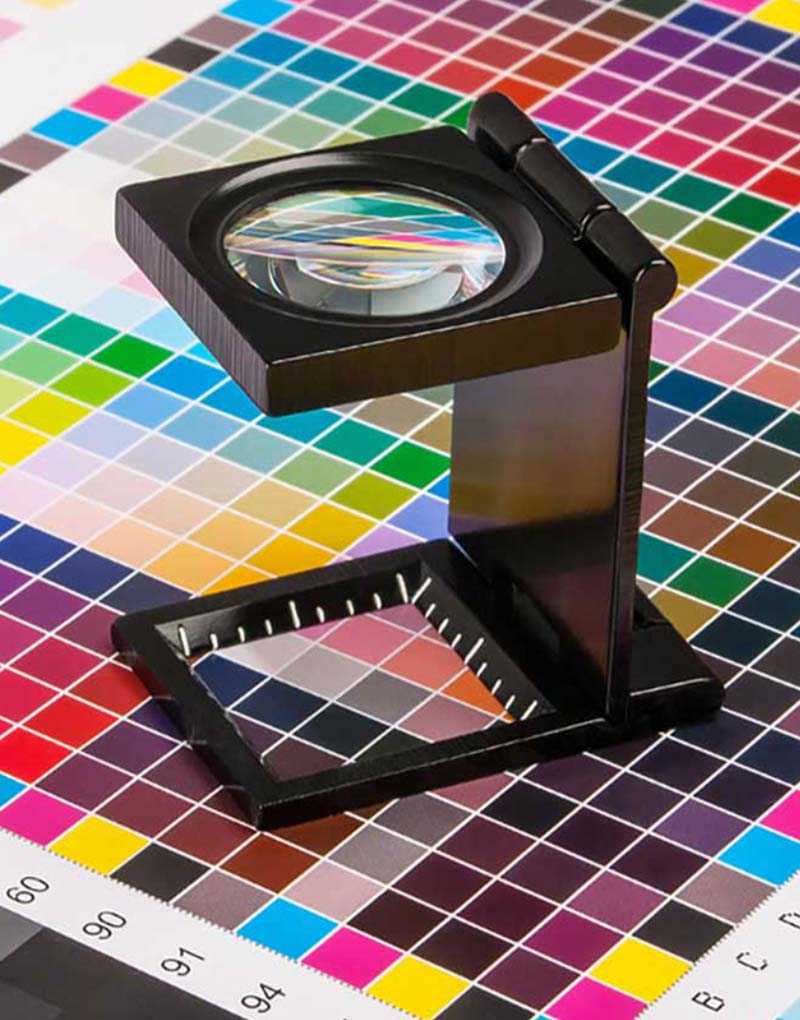

While the drying out process plays an essential role in litho printing, the scientific research of color mixing strategies holds equivalent value. This is an intricate process that includes the careful blending of main shades: cyan, magenta, and yellow, in differing percentages to attain a wide array of shades. The addition of black ink, referred to as 'crucial', assists in managing the intensity and deepness of the colors. The scientific research behind litho printing inks additionally takes into account the openness of the ink, which affects how shades overlay and mix. To accomplish a reliable shade mix, print professionals should also recognize the details of ink habits, color concept, and the physical buildings of the substratum on which the ink is used.The Art and Design Components in Litho Printing

Litho printing takes a breath life right into art and style through its unique aspects. Litho printing suits a range of shades, allowing artists to create vibrant and lively prints. This combination of accuracy and flexibility makes litho printing a preferred selection for many artists and designers.Modern Applications of Litho Printing Methods

Litho printing techniques have actually found comprehensive usage in the contemporary industrial market. Its impact and significance continue to expand with the development of brand-new advancements and modern technologies in the field. This section will explore these modern applications and the transformative duty they play in the printing sector.

Commercial Litho Printing Makes Use Of

Litho printing continues to be an essential component of the business sector. High-volume printing tasks, such as the production of books, papers, and packaging, rely on litho printing for its ability to deliver superior image high quality and expense performance. Litho printing additionally supplies a wide color range, premium to that of digital printing.Advancements in Litho Printing

Pressing the borders of typical strategies, contemporary advancements have actually sustained a host of developments in litho printing. One popular growth is digital litho printing, which incorporates the merits of digital technology with litho's top quality result. These innovations underscore the long-lasting relevance of litho printing in the modern globe.Exploring the Process of Litho Printing: Step by Action

Challenges and Solutions in Contemporary Litho Printing

In spite of the precision and custom that litho printing happily this contact form maintains, it is not without its collection of contemporary difficulties. Digital litho printing enables for cost-efficient brief runs and very easy modification, attending to the concern of variable information. Therefore, while there are difficulties, the litho printing market is proactively adapting to satisfy them head-on, ensuring its Bonuses relevance in the future.

Verdict

In verdict, litho printing, with its rich background and clinical complexities, holds a significant location in the print industry. The future of litho printing pivots on its capability to adjust to these altering demands, attesting its enduring worth in a progressing market.

Report this wiki page